BKM LININGS, EXPERT IN RUBBER LININGS

ABRASION RESISTANT RUBBER LININGS

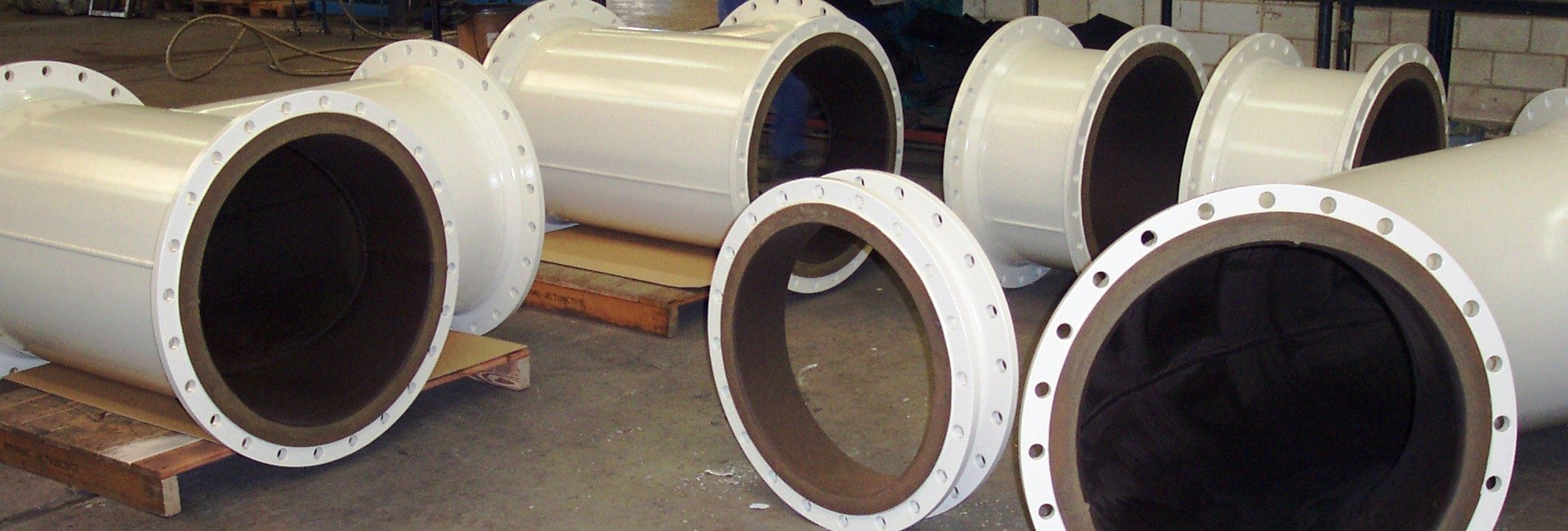

Our abrasive resistant rubber linings are applied in many industries. In the extraction of minerals, sand and gravel, there is extensive wear and tear to ducts, pumps and processing installations. For the various applications and types of wear, BKM Linings has a very diverse range of rubber qualities with characteristics focussed on various wear issues. The abrasive resistant rubber linings of BKM Linings have been successfully applied to:

- Flow meters

- Ducts

- Cyclones

- Pump housing

- Agitators

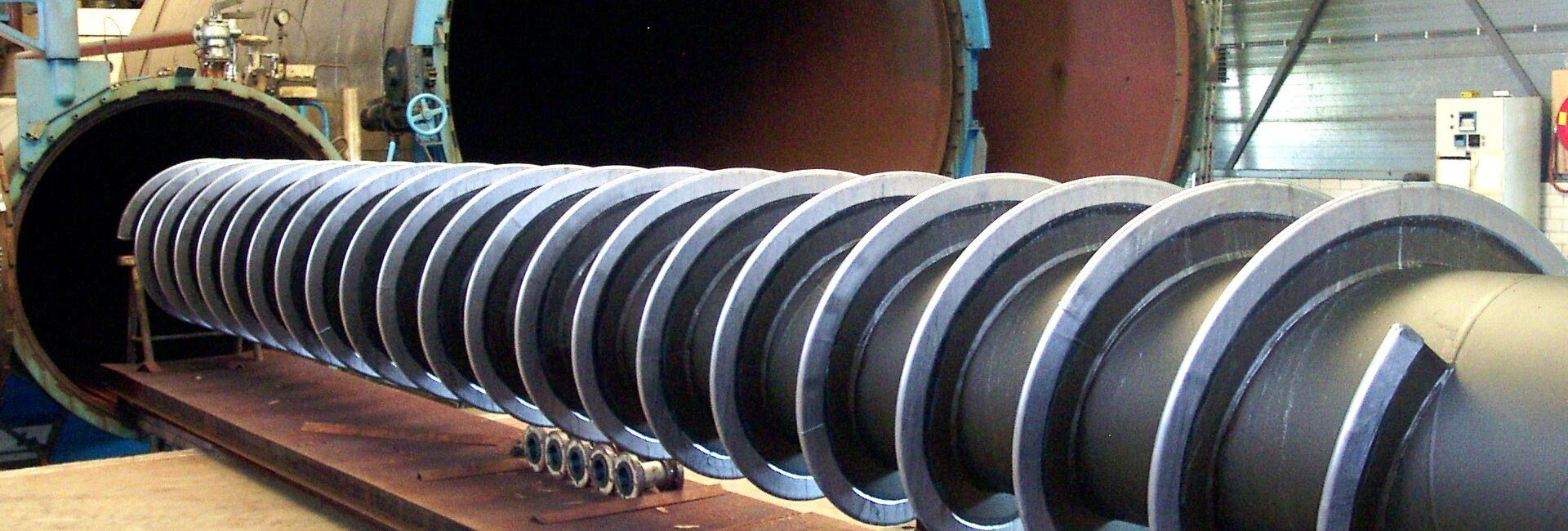

The parts coated with abrasive resistant rubber are used in the Power Industry, dredging industry, mining industry, sand and gravel extraction, off-shore and waste processing. The steel parts are blasted in-house and furnished with a rubber adhesive fixation. Then, one or more layers of rubbers are applied to the steel until the desired thickness is obtained. Through vulcanisation in one of our autoclaves, the rubber layer is homogenised and obtains the required hardness (Shore A). Also, an optimum fixation of the rubber to the steel surface is guaranteed.

CHEMICAL RESISTANT RUBBER LININGS

For the protection of installations that come into contact with aggressive mediums, BKM Linings has a wide range of chemical-resistant rubber linings. With our years of experience, we have obtained a lot of knowhow in rubber linings for:

- Flow meters

- Valves

- Agitators

- Ducts

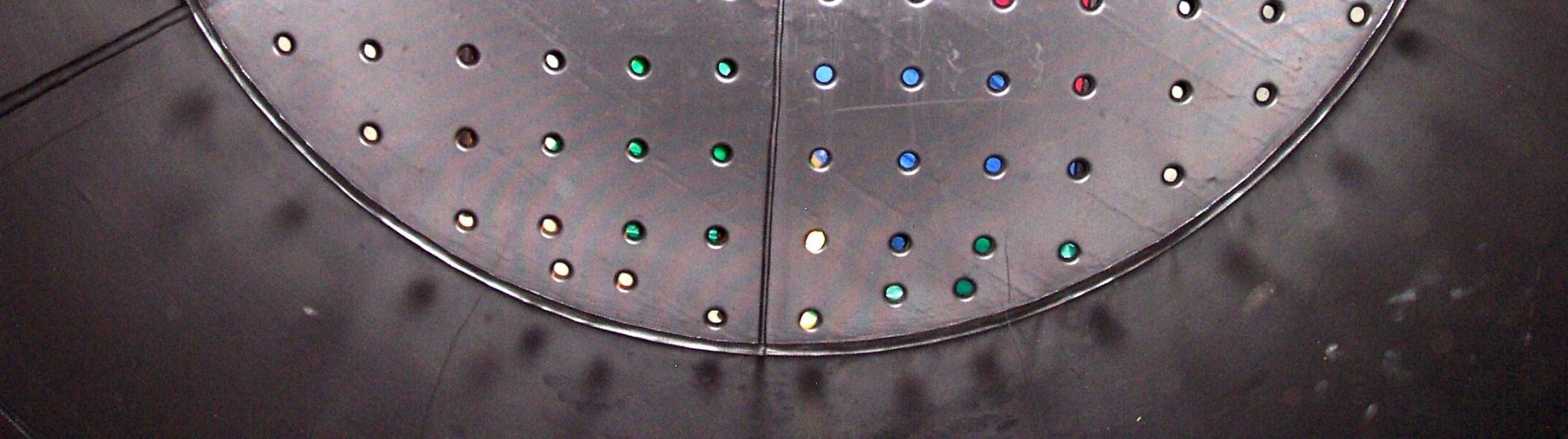

But also filter vessels, containers, electroplating installations, drums, water headers, and so on, can be furnished with a completely sealed rubber lining by our skilled liners and then vulcanised by pressure and temperature in one of our autoclaves. After that, there is always a visual inspection and an electric tightness test (spark test) of the rubber lining. Which type of rubber lining is best suited for the application is determined in close consultation with our customers.

BKM Linings bv.jpg)

+31(0)183-504909

Geplaats door BKM LININGS B.V.