BKM LININGS, EXPERT IN RUBBER LININGS

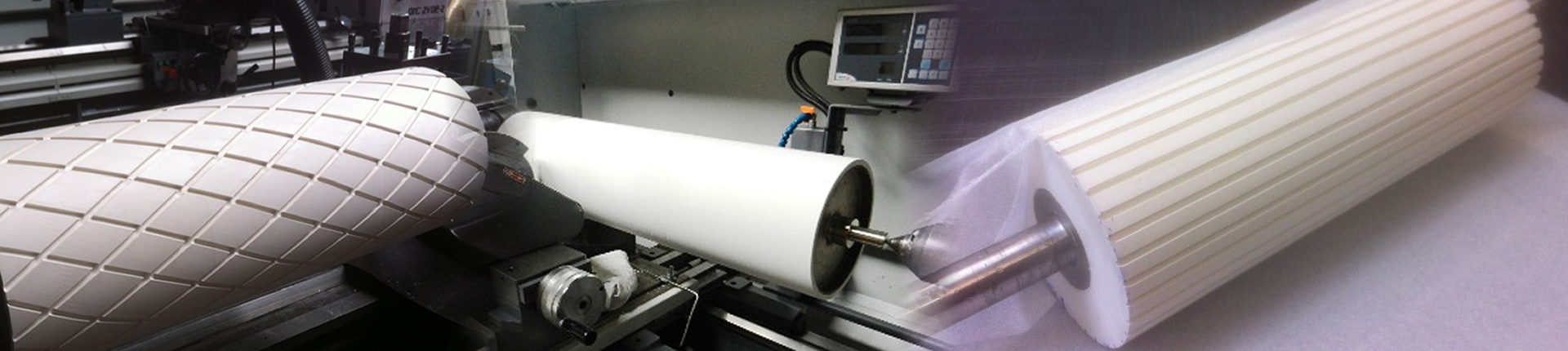

ROLLER LININGS

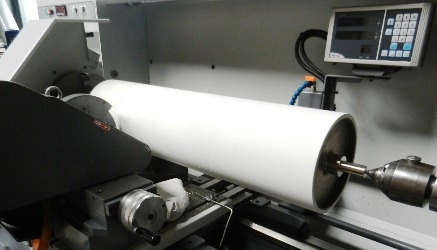

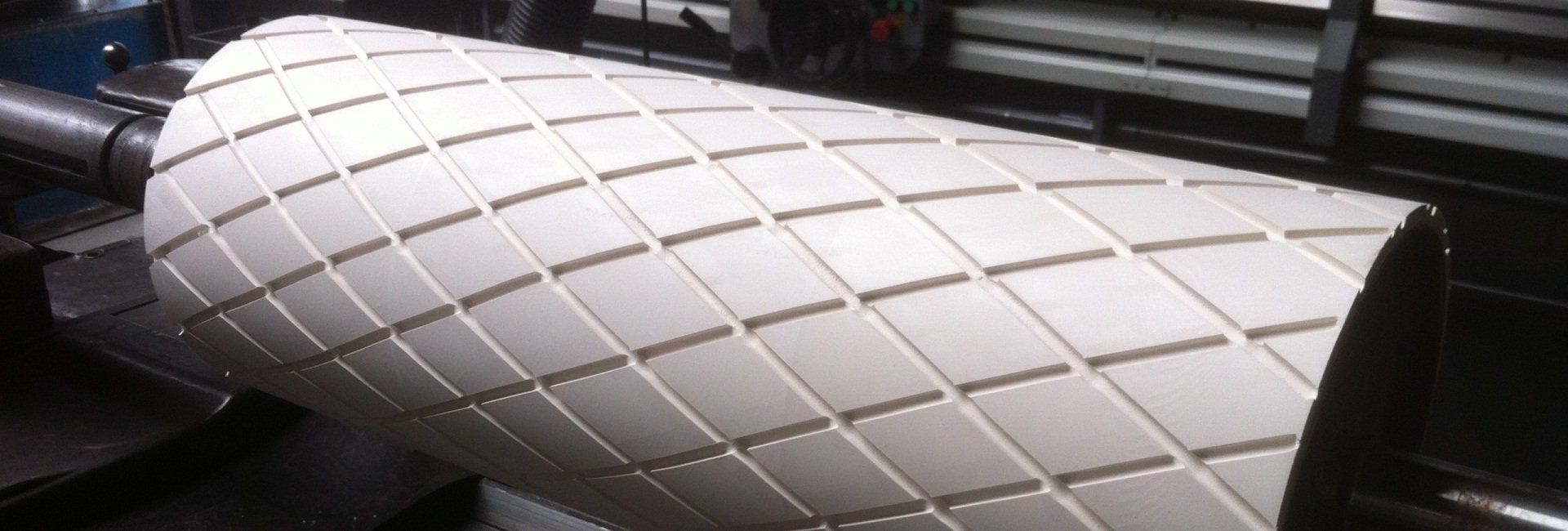

Rollers of various sizes and designs can be expertly furnished with a rubber lining. Based on the application and in consultation with the customer, the best rubber compound (in terms of hardness and composition) is determined to accomplish a lifespan as long as possible. Rollers are accurately machined, ground and, if desired, furnished with a profile.

BKM Linings rubberized rollers for the agrarian branch (haulm rollers, axial rollers, track rollers, peeling roller), industrial transport belts (drive rollers, rewind rollers, track rollers), food processing industry (rollers with rubber linings compliant with FDA requirements) and the offshore industry (track rollers, diabolo rollers, rewind rollers, cable rollers).

RECOVERING

Not only new rollers, but also used rollers can be furnished with a new rubber coating by BKM Linings. Firstly, the worn-out rubbers are removed from the roller. The steel is blasted clean and a new coat of rubber in the desired thickness and quality is vulcanised on the used steel roller. By doing so, our customers are spared the costs of purchasing completely new rollers.

RUBBER LINING FDA

Besides the widely applied black rubber roller linings, many rollers are furnished with non-marking rubber qualities. Usually, this involves rollers used in the food processing industry, whereby a non-marking rubber quality with a composition in compliance with the FDA requirements is necessary. BKM Linings has various rubber linings that comply with these types of specific requirements.

+31(0)183-504909

Geplaats door BKM LININGS B.V.